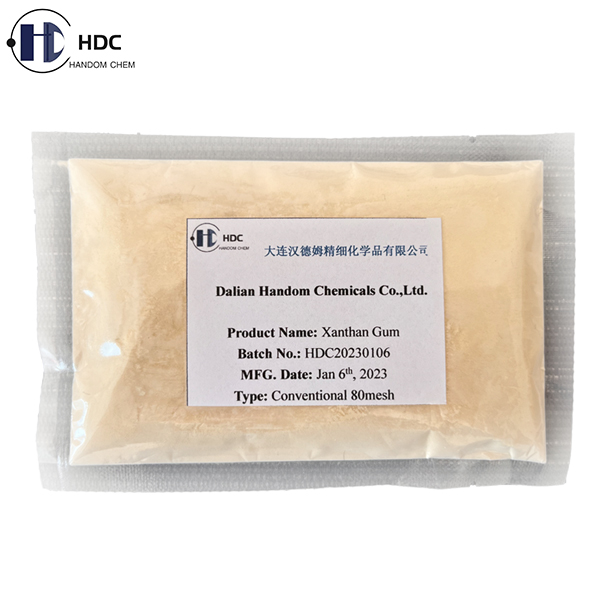

Xanthan Gum

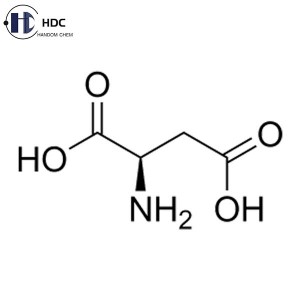

Chemical Structural Formula

Features

Xanthan gum is currently the bio-glue with the best performance in the world, which integrates thickening, suspension, emulsification and stabilization. The number of pyruvate groups at the molecular side chain end of xanthan gum has a great influence on its performance. Xanthan gum has the general properties of long-chain polymers, but it contains more functional groups than general polymers, and it will show unique properties under specific conditions. Its conformation in aqueous solution is diverse, and it exhibits different properties under different conditions.

| 1. Suspending and emulsifying: | Xanthan gum has a good suspending effect on insoluble solids and oil droplets. Xanthan gum sol molecules can form super-bonded ribbon-shaped helical copolymers to form a fragile glue-like network structure, so they can support the shape of solid particles, liquid droplets and air bubbles, showing strong emulsification stability and high suspension ability. |

| 2. Good water solubility: | Xanthan gum can quickly dissolve in water and has good water solubility. In particular, it can be dissolved in cold water, which can save complicated processing and is convenient to use. However, due to its strong hydrophilicity, if water is directly added and the stirring is insufficient, the outer layer absorbs water and swells into micelles, which will prevent water from entering the inner layer, thereby affecting the function, so care must be taken when using it correctly. Xanthan gum dry powder or mixed with dry powder auxiliary materials such as salt and sugar, and then slowly added to the stirring water to make a solution for use. |

| 3. Thickening: | Xanthan gum solution has the characteristics of low concentration and high viscosity (the viscosity of 1% aqueous solution is 100 times that of gelatin), and it is an efficient thickener. |

| 4. Pseudoplasticity:

|

Xanthan gum aqueous solution has high viscosity under static or low shearing action, and the viscosity drops sharply under high shearing action, but the molecular structure remains unchanged. And when the shear force is removed, the original viscosity will be restored immediately. The relationship between shear force and viscosity is completely plastic. The pseudoplasticity of xanthan gum is very prominent, and this pseudoplasticity is extremely effective for stabilizing suspensions and emulsions. |

| 5. Thermal stability:

|

The viscosity of xanthan gum solution will not change greatly with the change of temperature. The viscosity of general polysaccharides will change due to heating, but the viscosity of xanthan gum solution has almost no change between 10-80℃, even the low concentration xanthan gum aqueous solution still shows a stable high viscosity in a wide temperature range. 1% xanthan gum solution (containing 1% potassium chloride) is heated from 25°C to 120°C, and its viscosity only decreases by 3%. |

| 6. Stability to acid and alkali:

|

Xanthan gum solution is very stable to acid and alkali, its viscosity is not affected when the pH is between 5-10, and the viscosity changes slightly when the pH is less than 4 and greater than 11. In the range of PH3-11, the difference between the maximum and minimum viscosity is less than 10%. Xanthan gum can be dissolved in various acid solutions, such as 5% sulfuric acid, 5% nitric acid, 5% acetic acid, 10% hydrochloric acid and 25% phosphoric acid, and these xanthan gum acid solutions are quite stable at normal temperature, and their properties will not change for several months. Xanthan gum is also soluble in sodium hydroxide solution and has thickening properties, the resulting solution is very stable at room temperature. Xanthan gum can be degraded by strong oxidants, such as perchloric acid and persulfuric acid, and the degradation is accelerated as the temperature rises. |

| 7. Stability to salt:

|

Xanthan gum solution is miscible with many salt solutions (potassium salt, sodium salt, calcium salt, magnesium salt, etc.), and the viscosity is not affected. Under the condition of higher salt concentration, even in saturated salt solution, it still maintains its solubility without precipitation and flocculation, and its viscosity is hardly affected. |

| 8. Stability to enzymatic hydrolysis reaction:

|

The stable double helix structure of xanthan gum makes it highly resistant to oxidation and enzymolysis. Many enzymes such as protease, amylase, cellulase and hemicellulase cannot degrade xanthan gum. |

The Main Purposes

Due to its unique properties, xanthan gum is widely used in more than a dozen fields such as food, petroleum, medicine, and daily chemical industry. It has a high degree of commercialization and a wide range of applications, this is unmatched by any other microbial polysaccharide.

| 1. Food:

|

Xanthan gum is added to many foods as a stabilizer, emulsifier, suspending agent, thickener and processing aid. Xanthan gum can control the rheology, structure, flavor and appearance of the product, and its pseudoplasticity can ensure a good taste, so it is widely used in salad dressings, bread, dairy products, frozen foods, beverages, condiments, brewing, In confectionery, pastries, soups and canned foods. In recent years, people in more developed countries often worry that the calorific value in food is too high to make them fat. Xanthan gum dispels this concern because it cannot be directly degraded by the human body. In addition, according to a report in Japan in 1985, xanthan gum was the most effective anticancer agent among eleven food additives in a comparative test. |

| 2. Daily Chemicals:

|

The xanthan gum molecule contains a large number of hydrophilic groups, which is a good surface active substance and has anti-oxidation and anti-aging effects. Therefore, xanthan gum is used as the main functional ingredient in almost most high-end cosmetics. In addition, xanthan gum can also be used as a component of toothpaste to thicken and shape, reducing tooth surface wear. |

| 3. Medical Aspects:

|

Xanthan gum is the functional component of the hot microcapsule drug capsule in the world at present, and plays an important role in controlling the sustained release of drugs; due to its strong hydrophilicity and water retention,there are also many applications in specific medical operations, such as forming a dense water film to avoid skin infections; reducing thirst in patients after radiotherapy, etc. In addition, Li Xin and Xu Lei once wrote that xanthan gum itself can significantly enhance the humoral immune function of mice. |

| 4. Application in Industry and Agriculture:

|

In the petroleum industry, due to its strong pseudoplasticity, a low-concentration xanthan gum (0.5%) aqueous solution can maintain the viscosity of the drilling fluid and control its rheological properties, so the viscosity at the high-speed rotating drill bit is extremely small, which has saved the power ; while maintaining high viscosity in relatively static drilling parts, thereby preventing borehole wall collapse. And because of its excellent salt resistance and heat resistance, it is widely used in drilling in special environments such as oceans and high-salt areas, and can be used as an oil recovery agent to reduce dead oil areas and increase oil recovery. |

Specifications

| Testing Items | Specifications |

| Appearance | Cream White/Light Yellow Free Flowing Powder |

| The proportion of particles passing through the 80 mesh sieve | Not less than 95.00% |

| The proportion of particles passing through the 200 mesh sieve | Not more than 57.00% |

| Loss on Drying | Not more than 13.00% |

| pH Value(1% Xanthan Gum solution) | 6.0 ~ 8.0 |

| Ash | Not more than 15.00% |

| Shearing Ratio | Not less than 6.50 |

| Viscosity(1% Xanthan Gum in 1% KCl solution) | 1200 cps ~ 1700 cps |

| Pyruvic Acid | Not less than 1.5% |

| Total Nitrogen | Not more than 1.5% |

| Total Heavy Metals | Not more than 20ppm |

| Lead(Pb) | Not more than 2ppm |

| Total Plate Count | Not more than 2000CFU/g |

| Coliforms/5g | Negative |

| Yeasts & Moulds | Not more than 500CFU/g |

Packaging

25kg net kraft paper bag.

Storage Conditions

Preserved in unopened containers in a cool dry place before using; kept away from direct sunlight, heat and moisture.