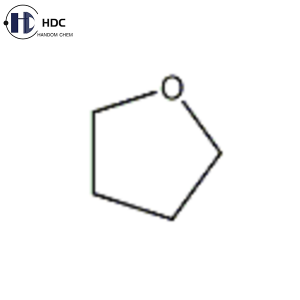

Tetrahydrofuran

Brief Introduction:

Tetrahydrofuran, also known as oxolane or THF, is a heterocyclic organic compound with the chemical formula C4H8O. It belongs to the ethers and is the complete hydrogenation product of furan. It is a colourless and transparent liquid, soluble in water, ethanol, ether, acetone, benzene, etc., mainly used as solvent, chemical synthesis intermediate, and analytical reagent.

Specifications of our Tetrahydrofuran(THF):

| Test Items | Specifications |

| Tetrahydrofuran Purity | Not less than 99.95% |

| Colour (Pt-Co) | Not more than 5 |

| Water Content | Not more than 0.015% |

| Hydrogen Peroxide Content | Not more than 0.003% |

| BHT Content | 90μg/g ~ 150μg/g |

Applications of our Tetrahydrofuran(THF):

1) Tetrahydrofuran is an important raw material for organic synthesis and a solvent with excellent performance. It is especially suitable for dissolving PVC, polyvinylidene chloride and butylaniline. Widely used as a solvent for surface coatings, anti-corrosion coatings, printing inks, tapes and film coatings, and as a reaction solvent. When used in electroplating aluminum liquid, the thickness and brightness of the aluminum layer can be controlled arbitrarily.

2) In the pharmaceutical industry, Tetrahydrofuran (THF) is used to synthesize Pentoxyverine Citrate, Rifamycin, Progesterone and some hormone drugs.

3) In organic synthesis, it is used to produce tetrahydrothiophene, 1.2-dichloroethane, 2.3-dichlorotetrahydrofuran, adiponitrile, adipic acid, hexamethylenediamine, succinic acid, butylene glycol, valerolactone, butyrolactone and pyrrolidone, etc.

4) Tetrahydrofuran can be directly used to make synthetic fibers, synthetic resins, and synthetic rubber.

5) Used as an intermediate for synthesizing the pesticide Fenbutatin Oxide.

6) THF is treated with hydrogen sulfide to form tetrahydrothiophenol, which can be used as an odorant (identification additive) in fuel gas.

7) THF can also be used as a surface treatment agent for synthetic leather.

Operation Precautions:

1) Closed operation, fully ventilated.

2) Operators must undergo special training and strictly abide by operating procedures. It is recommended that operators wear filter gas masks (half masks), safety glasses, anti-static overalls, and rubber and oil-resistant gloves.

3) Keep away from fire and heat sources. Smoking is strictly prohibited in the workplace.

4) Use explosion-proof ventilation systems and equipment.

5) Prevent vapor from leaking into the workplace air.

6) Avoid contact with oxidants, acids, and alkalis.

7) The flow rate should be controlled during filling, and a grounding device should be installed to prevent the accumulation of static electricity.

8) Load and unload with care when handling to prevent damage to packaging and containers.

9) Equipped with corresponding varieties and quantities of fire-fighting equipment and leakage emergency treatment equipment.

10) Empty containers may contain harmful substances.

Packaging:

180kg/Iron Drum, IBC or ISO Tank.

Storage Notes:

1) Generally, polymerization inhibitors should be added to products.

2) Store in a cool, ventilated warehouse. Keep away from fire and heat sources. The storage temperature should not exceed 30℃.

3) The packaging must be sealed and must not come into contact with air. They should be stored separately from oxidants, acids, alkalis, etc., and avoid mixed storage.

4) Use explosion-proof lighting and ventilation facilities. It is prohibited to use mechanical equipment and tools that are prone to sparks.

5) The storage area should be equipped with leakage emergency treatment equipment and suitable containment materials.

Shelf Life:

9 months if stored under above mentioned conditions.