POLY(D,L-LACTIDE-CO-GLYCOLIDE)

Brief Introduction:

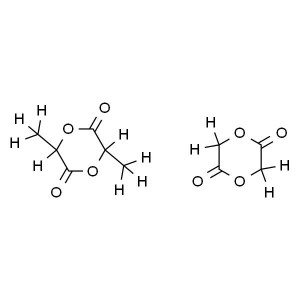

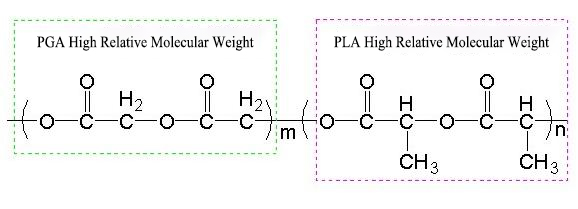

POLY(D,L-LACTIDE-CO-GLYCOLIDE), the abbreviation is PLGA, also known as polylactic acid-glycolic acid copolymer, which is made from the random polymerization of two monomers, lactic acid and glycolic acid.

It is a degradable functional polymer organic compound with good biocompatibility, non-toxicity, good capsule-forming and film-forming properties, and is widely used in pharmaceuticals, medical engineering materials and modern industrial fields.

Specifications of our POLY(D,L-LACTIDE-CO-GLYCOLIDE):

| Test Items | Specifications | Test Methods |

| Appearance | White or yellow particles | Visual |

| Intrinsic viscosity | 0.2 dL/g ~ 2.5 dL/g | Ubbelohde viscometer |

| Viscosity-average Molecular Weight | 1 ~ 400000 | Ubbelohde viscometer |

| Number-average molecular weight | 1 ~ 400000 | Gel permeation chromatography(GPC) |

| Glass transition temperature | 40℃ ~ 60℃ | Differential thermal analysis and differential scanning calorimetry |

| Melting point | --- | --- |

| Residual monomer | Less than 1% | Gas chromatography, liquid chromatography |

| Residual solvents | Less than 0.05% | Gas chromatography, liquid chromatography |

| Heavy metals | Less than 10 ppm | Colorimetry, atomic absorption spectroscopy |

| Density | 1.20g/cm3 ~ 1.30g/cm3 | --- |

| Sulphated ash | Less than 0.05% | Burn at high temperature and weigh the remaining residue |

Applications of our PLGA:

First of all, PLGA materials have good biocompatibility, can be compatible with human tissues and have no toxic side effects. The material can be gradually degraded and metabolized by human tissue, avoiding the need for secondary surgery to remove the material, thereby reducing patient pain and recovery time. Compared with other biodegradable materials, PLGA materials have higher biocompatibility and are less likely to cause inflammatory reactions and immune rejection.

Secondly, the degradation rate of PLGA materials can be adjusted according to clinical needs. The medical field often has strict requirements on the degradation rate of materials. By adjusting the proportion of its copolymer, PLGA materials can be degraded from days to years. This controllable degradation property makes PLGA materials an ideal choice for sustained-release drug delivery systems, and appropriate dosing regimens can be designed according to the patient's specific conditions and treatment needs.

Finally, PLGA materials also have good mechanical properties and can meet the mechanical properties requirements of medical devices. In clinical applications, PLGA materials are often used to prepare medical devices such as stents, sutures, and fillers to achieve tissue repair and regeneration. Its excellent mechanical properties not only provide sufficient mechanical support, but also maintain the stability and reliability of the material.

In summary, POLY(D,L-LACTIDE-CO-GLYCOLIDE), as a biodegradable material in the medical field, has excellent performance in biocompatibility, degradation rate adjustment and mechanical properties. It is widely used in medical devices and drug delivery systems, bringing many benefits to the medical industry. With the continuous advancement of science and technology and medicine, it is believed that PLGA materials will play a more important role in the future development of the medical field.

Packaging:

10g/bag, 20g/bag, 30g/bag, 50g/bag or 100g/bag.

Storage Method:

♔ This series of products are biodegradable materials. During storage, contact with reagents that can cause product degradation should be avoided, including water, acidic substances, alkaline substances, and alcohols.

♔ During the storage process, this series of products should be sealed, dried and stored at low temperature (refrigerator -20℃), and should be sealed with a sealing machine (remaining products after use must not be packaged and stored in ziplock bags).

♔ When using, take it out of the refrigerator and leave it at room temperature, wait until the temperature reaches room temperature and wipe off the condensed moisture on the surface of the packaging bag before opening it (take it out of the refrigerator and open it at a constant temperature, moisture in the air will condense on the surface of the product, causing the product to degrade). The ambient air humidity during use should be less than 35% to prevent the remaining products from getting damp and affecting product quality.

♔ Avoid contact with eyes, skin, etc. If contact occurs accidentally, rinse with plenty of water and seek medical advice.

Shelf Life:

24 months if stored in unopened original containers away from heat and moisture.